Advanced Steel Laser Cutting

Get the Trusted Laser Cutting Services In Melbourne!

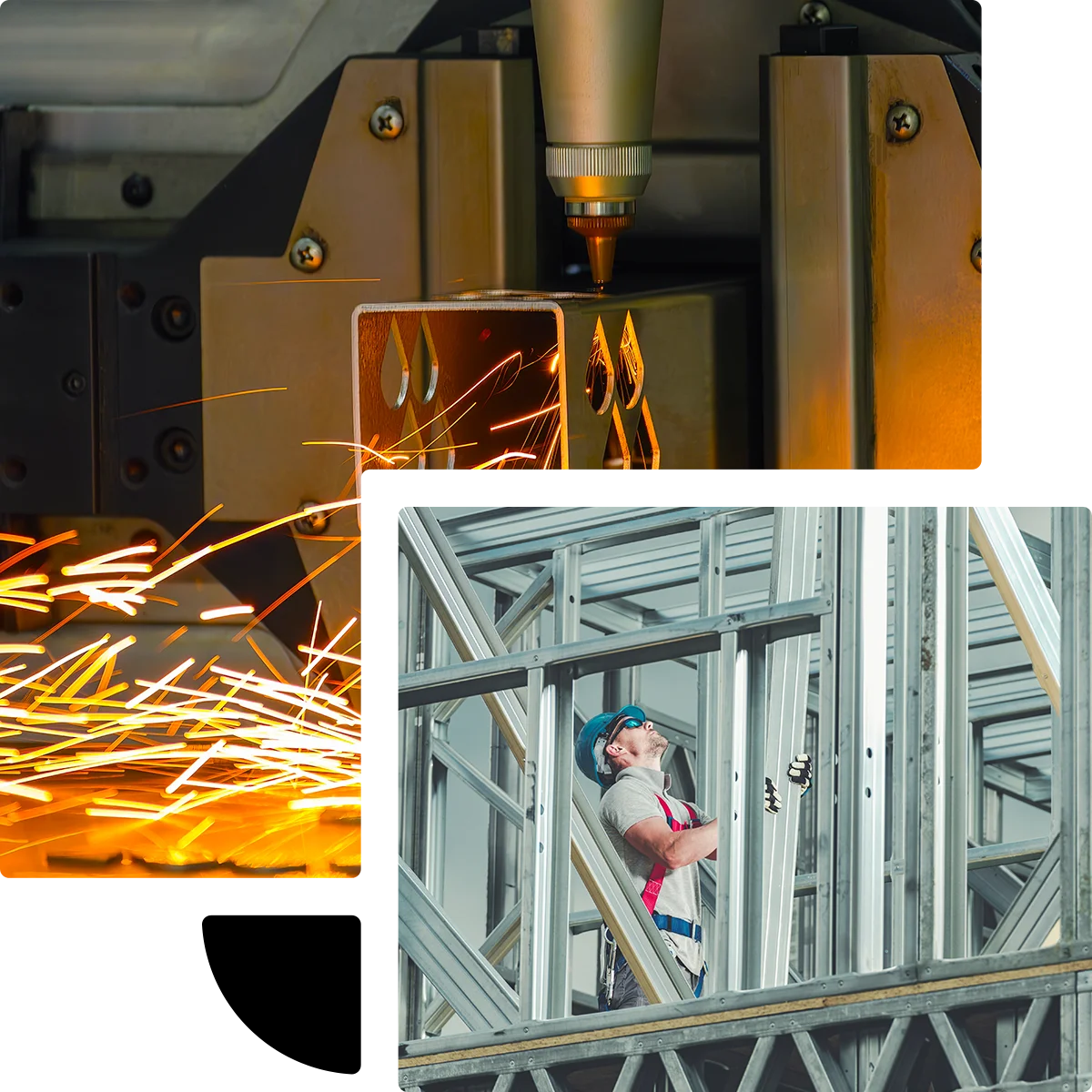

Ensuring precise measurements and consistent designs is crucial for the success of construction projects, the automotive industry, medical devices, and even intricate electronic circuit boards. Recognizing this importance, Newgen Steel emerges as your dependable partner to bring your design to life through our laser-cutting services.

We are a skilled team with over 10 years of experience in the drafting, fabrication and laser-cutting industry. Over the years, we have refined and perfected our laser-cutting services for Melbourne and surrounding businesses. Using technologically advanced machinery and attachments, we bounce between different processes, ensuring desirable results every time.

Teaming with us for your laser cutting needs provides you with a team that:

- Prioritises transparent communication

- Possesses technical knowledge and can guide you with designs

- Meets tight deadlines

- Seeks solutions to minimise wastage

- Offers post-processing services such as Folding

Precision Laser Cutting For Steel And Other Metals

10 Years Experience

Our proven work experience as steel suppliers and fabricators guarantees long-lasting, reliable products.

Efficient Project Completion

With in-house 3D technology, we minimise downtime and assist in ensuring within-budget project completions.

Timely Delivery

We deliver quality steel fabrication, from start to finish, efficiently, preventing costly delays and setbacks.

Public Liability Coverage

The public liability insurance up to $20 million guarantees one unparalleled peace of mind.

Our advanced steel laser cutting process ensures efficiency and precision.

Using advanced technology, we deliver steel laser cutting services in Melbourne with precision and consistent quality.

Initial Dialogue

Clear communication drives project success. We detail requirements, ensuring you're informed at every project stage.

Strategic Blueprint

Detailed planning sets the foundation, transforming your vision into a precise, actionable fabrication strategy.

Expert Craftsmanship

Accuracy acquired with laser cutting and rigorous testing guarantees flawless fabrication, ensuring structural integrity from the start.

Guaranteed Execution

Being on time and within budget are among our core mottos that assist us in building lasting trust.

Exploring our diverse laser cutting options for steel in Melbourne.

Almost every business, from small to large scale, requires laser-cutting services. For the construction industry, it serves in metal works and crafting HVAC systems. Similarly, the automotive industry requires intricate body panels, exhaust systems and other interior components for optimal functioning. All of these have varied cutting requirements. Through our cutting-edge machinery, we cater to all these cutting types.

Our rotary laser cutting steel attachments are suitable for engraving curved designs. These include:

- Logos or text cut into the surface of pipes

- Serial numbers, barcodes, or branding on cylindrical products

- Spiral cuts or helical patterns on tubes

- Designs, text, or patterns around the entire circumference of rings or collars

- This is valuable for industrial fittings and custom components.

- Complex contour shapes on conical objects allows for precise shaping and customisation of conical forms.

- Perforated patterns on cylindrical screens

- Custom threads onto the inside or outside of pipes and tubes

Apart from complex patterns, we also craft square, clean, burr-free edges with our flat sheet laser cutting attachments.

Talk to Us Today – Request a Call Back

Reach Out for High-Quality and

Get the precision and adaptability you need for your steel laser-cutting projects. Reach out for a callback, and let us show you our capabilities.

Maximise Output and Minimise Costs with

When consistency is paramount, even minor deviations can disrupt project timelines and budgets. We prioritise high repetition tolerance by meticulously calibrating our machinery and leveraging advanced CNC controls to ensure each cut is identical. This focus on precision reduces inconsistencies and streamlines production. To further enhance efficiency and reduce costs, we employ:

- Advanced Nesting Software:This optimises material usage, minimising waste and directly translating into cost savings.

- Realistic Turnaround Times:We understand the importance of tight deadlines, provide accurate estimates, and communicate progress throughout the process.

- Controlled Laser Parameters: These ensure precise adjustments to power and speed, rendering clean, sharp edges and minimal heat-affected zone (HAZ), i.e. distortion.

Our commitment to transparency extends to our pricing structure. With our clear and detailed quotes, we eliminate unexpected costs and ensure budget predictability.

This comprehensive steel laser cutting approach allows our clients to achieve their project goals with confidence, knowing they’re partnering with a team dedicated to maximizing output without extra expenses.

Frequently Asked Questions

Steel laser cutting offers significant advantages. These include:

- Extremely accurate cuts

- Minimal chances of errors

- Smooth edges in the first time

- Reduced need for secondary finishing

- Reduced material loss due to narrow kerf (cutting width)

- Rapid production due to automation

- Quick adjustments in case of design variations

- Ideal for industries needing tight tolerances: automotive, aerospace, electronics

Steel laser cutting is versatile and can be applied to various steel types, including hardened or specialised. However, limitations do exist. Here’s an overview:

Applicable Steel Types

- Mild steel

- Stainless steel

- Some hardened alloys

Limitations

- Maximum thickness depends on laser power

- Hardened and high-alloy steels require specialised lasers

- Material properties (thermal conductivity, reflectivity) affect cutting efficiency

- Consultation with experts is important for specific material and thickness feasibility

The heat from Melbourne’s laser cutting services can affect material properties, but mitigation measures are taken. Here are a few:

- Controlled laser power, speed, and focus

- Assist gases (nitrogen, oxygen) for cooling

- Pulsed laser techniques for thin materials

- Optimised cutting parameters and cooling for thicker materials

- Post-processing: Stress relieving or heat treating

Through our post-processing services, we aim to enhance the efficiency of our services. The available services during this phase are:

- Deburring and grinding

- Polishing

- Coating (powder coating, plating)

The enhancements happening due to the above include:

- Improved safety and aesthetics

- Smooth finish

- Corrosion resistance and durability

The handover time for every project can vary, and it’s not feasible to quote before understanding the scope. Once we have a complete walkthrough of the work, we quote accurate timelines and stick to those. Typical lead times depend on:

- Complexity

- Volume

- Material availability

In case there is a rush order, our team:

- Conducts flexible scheduling to optimise the workflow

- Conduct detailed communication with the client and team members

- Prioritise production and material sourcing

- Expedite every aspect of our service